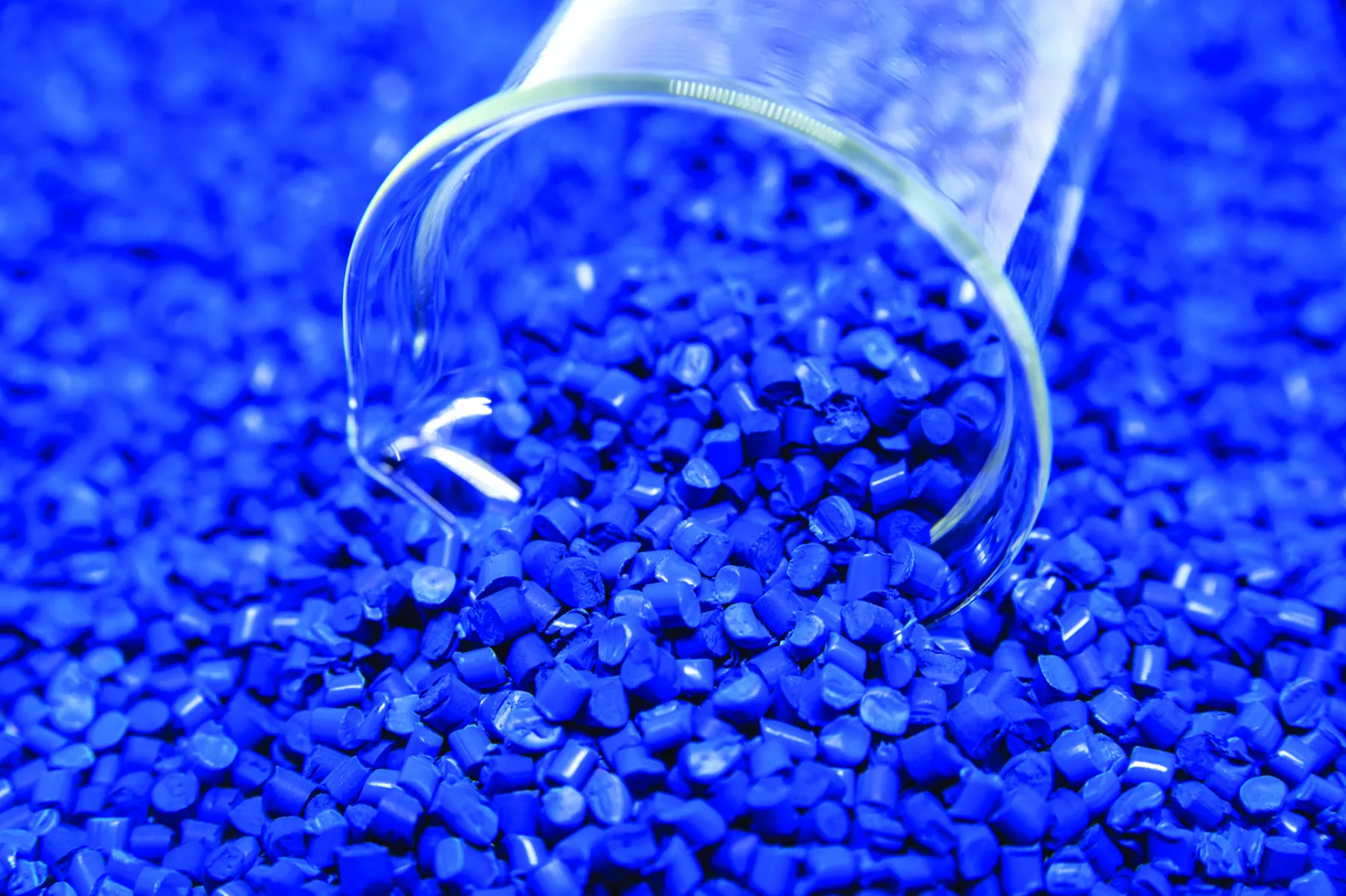

Granules, as one of the essential and widely used products in various industries, are employed extensively in manufacturing processes and industrial applications. These materials are essentially a type of raw material produced in the form of small, uniform particles. Due to their specific physical and chemical properties, granules find applications in many industries, including plastics, chemicals, pharmaceuticals, and food.

Granules, due to their specific physical and chemical characteristics, have become one of the most essential raw materials in various industries. The use of granules in production processes increases efficiency, reduces waste, and improves the quality of final products. Given the wide applications of granules in the plastics, pharmaceutical, food, and chemical industries, it can be said that this material plays a significant role in the development and progress of various sectors.

Definition of Granules

The word “granule” is derived from the Latin word “granulum,” meaning grain. Granules are essentially solid materials that have been formed into small particles or pieces. These particles typically range in size from a few millimeters and, due to their uniform shape and size, are optimized for use in industrial machines. One of the most significant characteristics of granules is that their physical shape allows them to easily fit into devices and be processed quickly in manufacturing processes.

Applications of Granules

The granule production process involves several stages, which may vary depending on the type of material and the industry in which they are used. Generally, the main stages of granule production are as follows:

Raw Material Preparation: First, the raw materials are prepared in their initial form. These materials can include polymers, chemicals, or pharmaceuticals.

Extrusion: In this stage, the raw materials are subjected to pressure and temperature to melt them. The molten material is then passed through an extrusion machine, forming into thin strands.

Cutting and Cooling: After exiting the extrusion machine, the strands of molten material are cut into small particles (granules). These particles are then cooled and solidified.

Packaging: Finally, the produced granules are packaged and prepared for use in various industries.

Advantages of Using Granules

The use of granules in various industries offers numerous advantages, some of which are highlighted below:

Uniformity and Predictability

One of the main advantages of using granules is their uniformity. Their consistent size and shape make them easier to control in manufacturing processes, reducing error rates. This uniformity also ensures that the quality of the final products is better and more predictable.

Waste Reduction

Using granules in industrial processes can lead to reduced waste. Because these materials are directly used in production without the need for additional processing, the amount of waste generated is minimized. This is especially important in industries like plastics and pharmaceuticals, where precision and product quality are crucial.

Ease of Transportation and Storage

Granules are easier to transport and store compared to powdered or liquid materials, due to their physical form. Granules are typically more compact than powders, taking up less space. Moreover, transporting granules is safer as there is less risk of leakage or spillage compared to powdered or liquid substances.

Efficiency in Production

Granules, due to their ease of processing and control, enhance the efficiency of production processes. Industrial machines that work with granules generally operate faster and with greater precision. This leads to the production of products at a higher speed and quality.

Applications of Granules

Depending on the type of material they are made from, granules have various applications. Below are some common uses of granules across different industries

1. Plastics Industry

One of the most important and widespread uses of granules is in the plastics industry. Plastics are primarily produced through processes like extrusion and injection molding. Plastic granules, due to their regular shape and uniform size, are used as raw materials in these processes. Injection molding and extrusion machines are designed to use granules as input since these materials easily melt and take the final shape of the product. Additionally, using granules ensures that the production of plastics is more precise, reducing waste levels.

2. Pharmaceutical Industry

In the pharmaceutical industry, granules are used as intermediates in the production of drugs. In this sector, granules are utilized to produce tablets and capsules. Typically, solid medications are initially made in the form of granules and then transformed into tablets or capsules through various processes. Using granules in pharmaceuticals ensures a better distribution of active ingredients within the drug, leading to more accurate dosage.

3. Food Industry

Granules are also used in the food industry. In the production process of many food items, granules serve as raw materials. For instance, in the production of powdered food products like milk powder or cocoa powder, granules are used to facilitate packaging and transportation. Additionally, granules are employed in the production of food additives and preservatives. An important characteristic of granules in the food industry is that they allow for better control during production processes, reducing errors and improving the quality of the final product.

4. Chemical Industry

In the chemical industry, granules are used as intermediates in the production of various chemical products. Many chemical substances that are sold in powder or liquid form are initially produced as granules. These substances are then converted to their final state through various processes. One advantage of using granules in the chemical industry is the reduced risks associated with transportation and storage, as granules are typically more stable and safer than powders or liquids.