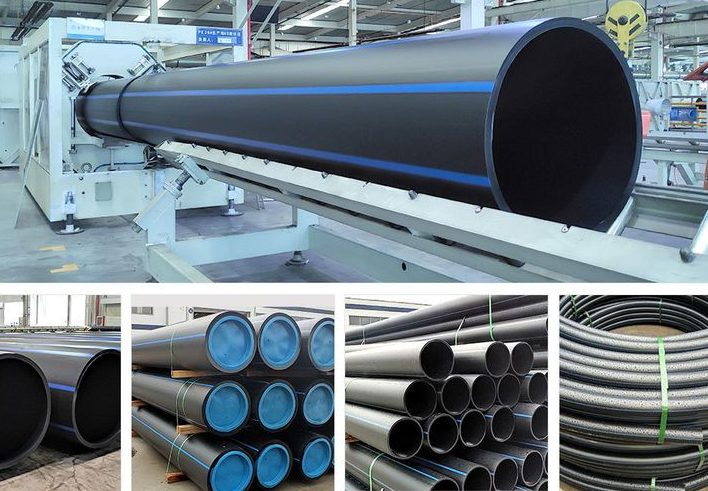

In today’s world, the use of polymers—especially polyethylene—has significantly increased across various industries. One of the most important applications of polyethylene is in the production of different types of pipes and fittings. In this article, we aim to provide a comprehensive, simple, and practical overview of the different grades of polyethylene, their differences, applications of polyethylene pipes, and the various types of fittings.

Why Polyethylene Pipes?

Before diving into the discussion about grades, it’s good to understand why many professionals in industrial, civil, agricultural, and urban projects choose polyethylene pipes as their first option.

The advantages of polyethylene pipes include the following:

| Feature | Description |

|---|---|

| Lightweight and easy transport | Their low weight reduces transportation costs. |

| Corrosion resistance | They offer high resistance against chemicals, acids, and alkalis. |

| High flexibility | They are easy to install and can withstand mechanical stress and ground movement. |

| Long lifespan | Depending on usage conditions, they can last over 50 years. |

| Excellent connectivity | They support various connection methods like butt fusion, threaded fittings, and electrofusion. |

Polyethylene Pipe Grades: From PE63 to PE100

The polyethylene used in pipe production comes in different grades, mainly differing in density, mechanical strength, durability, and pressure resistance. Let’s take a closer look at each of these grades:

1. PE63 Grade

This was one of the most commonly used polyethylene grades for pipe production in the past. However, today it is not cost-effective due to its low density and the need for thicker pipe walls.

Features: Bulky, heavy, requires more raw material

Former applications: Low-pressure piping systems

Current status: Nearly obsolete

2. PE80 Grade

PE80 has a higher density than PE63, allowing for thinner pipe walls and reduced overall pipe weight. This leads to material savings and lower production costs.

Features: Adequate strength, lighter than PE63

Applications: Sewage pipes, corrugated pipes, light water supply systems

Important note: Suitable for systems that do not require very high pressure

3. PE100 Grade

PE100 is the newest and most advanced grade of high-density polyethylene (HDPE). Its high density and compact molecular structure allow for the production of pipes with thinner walls but greater strength.

Features: High resistance to pressure, UV radiation, and chemicals

Applications: Gas transportation, water transmission lines, pressurized irrigation systems, industrial wastewater

Our recommendation: If you’re looking for high quality and long service life, PE100 is the best choice.

Comparison of PE63, PE80, and PE100 Grades

| Grade | Pressure Resistance (atm) | Pipe Wall Thickness | Application | Status |

|---|---|---|---|---|

| PE63 | 63 | High | Older projects | Obsolete |

| PE80 | 80 | Medium | Sewage, corrugated pipes, agriculture | Common |

| PE100 | 100 | Low | Drinking water, gas, pressurized irrigation | Widely used |

Types of Polyethylene Pipes and Their Applications

Water Supply Polyethylene Pipes

Used for the transportation of drinking water. These pipes must be made from virgin material and certified for potable water use. They are flexible, wear-resistant, and have a long service life.

Sewage Polyethylene Pipes

Designed for the transportation of industrial and municipal wastewater, as well as surface water collection and drainage systems. They are commonly made from PE80 grade.

Gas Distribution Polyethylene Pipes

Suitable for transporting natural gas. These pipes must be manufactured from high-quality materials such as black PE100 and must pass multiple safety tests.

Cable Protection Polyethylene Pipes

Used for housing electrical and fiber-optic cables. Their key features include resistance to moisture, impact, and corrosion.

Polyethylene Fittings and Their Types

Fittings play a very important role in the implementation of piping networks. There are different types of fittings, each chosen based on the application, environmental conditions, and system pressure:

- Butt Fusion Fittings

- Electrofusion Fittings

- Mechanical and Threaded Fittings

- Special Irrigation Fittings (Drip and Sprinkler)

Each type of fitting is suitable for a specific type of project. For example, electrofusion fittings are typically used for gas pipelines, which create a completely sealed and safe connection.

Most Common Grades of Polyethylene Materials in Pipe and Fitting Production

Below are some examples of polyethylene grades used in the production of pipes and fittings:

- PE100 (CRP100N)

- Feature: Very high resistance to cracking and pressure

- Application: Drinking water, gas, wastewater, and agricultural pipes

- PE100 Black (CRP100B)

- Feature: UV resistant, suitable for outdoor use

- Application: Outdoor gas and water pipes and main transmission lines

- PE80 (EX3)

- Feature: Good impact resistance and ESCR (Environmental Stress Cracking Resistance)

- Application: Agricultural pipes, wastewater pipes, some fittings

Conclusion

Considering the wide range of applications and unique properties of polyethylene pipes and fittings, the correct selection of the raw material grade can directly impact the quality, durability, and cost of a project. We suggest using PE100 grade for more sensitive projects, as it is more economically and technically cost-effective. Also, sufficient care should be taken in selecting fittings so that the type of fitting is compatible with the project conditions.

If you are also involved in the production or implementation of pipelines, the accurate selection of the grade and familiarity with different types of pipes and fittings can pave the way for the success of your project. Please share your experiences in this field with us.