If you are active in the field of polymers and related industries, you have surely heard the name PVC multiple times. PVC, or Polyvinyl Chloride, is one of the most widely used and valuable polymers in the world. Due to its unique properties, it has earned a special place in various industries, especially in construction. In this article, we will introduce you to this remarkable material with a comprehensive and practical perspective.

A Brief History

The first attempts at commercial use of PVC date back to the early 20th century. However, the rigidity and brittleness of this polymer initially hindered its widespread application. Finally, in 1926, Waldo Semon succeeded in transforming it into a flexible material by adding polymer additives, paving the way for its industrial use.

PVC Production Methods

There are five main methods used for the production of PVC, each with its unique characteristics:

Suspension Method (S-PVC): The most common method of production, covering about 80% of the global market. It is suitable for transparent products with low water absorption.

Emulsion Method (E-PVC): Performed with the help of emulsifiers, and its output is used for making artificial leather, gloves, and wallpaper.

Bulk Polymerization Method: Similar to the suspension method but with tighter control, suitable for producing specialized compounds.

Solution Method: In this method, the monomer is dissolved in an organic solvent, and the polymer is simultaneously formed in that same solvent.

Precipitation Method: Very similar to the solution method, but here, the polymer does not dissolve in the solvent and precipitates at the end of the reaction.

Types of PVC

PVC is divided into three types, each with its specific applications:

Rigid PVC (UPVC)

This type contains no plasticizers and is used in the production of pipes, window profiles, and fittings. Its main features include high resistance to pressure, impact, and environmental conditions.Flexible PVC (PVC-P)

By adding plasticizers such as DOP, this type becomes flexible. It is used in the manufacture of hoses, shoes, clothing, and packaging materials.Modified PVC (MPVC)

This type has enhanced physical and mechanical properties. It is lighter, more durable, and suitable for applications requiring high endurance.

Distinctive Features of PVC

High tensile and impact strength

Resistance to corrosion, abrasion, and scratches

Excellent thermal and sound insulation

High durability against weather conditions

Affordable and cost-effective

Resistant to UV, oils, and chemicals

High processability for manufacturing various products

Applications of PVC in Various Industries

PVC is used in both rigid and flexible forms, each with a wide range of applications across different industries.

Flexible Type

Hoses and Flexible Pipes:

Used in irrigation, household, and industrial applications with high resistance.

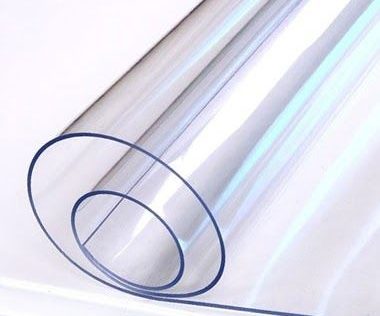

Soft Sheets and Films:

Applied for covering tanks, rooftops, tablecloths, and protective sheets.

Calendering:

Production of soft foils and films by passing the material through rollers.

Footwear Industry:

Used for durable soles, sandals, boots, and indoor shoes.

Plastic Cans and Parts:

Resistant to chemicals, heat, and oil.

Cable Coating:

Ideal for safe electricity transmission and resistant to environmental factors.

Floor Coverings:

Used in homes, vehicles, and public spaces.

Clothing:

Manufacture of synthetic leather (rexine) for garments, bags, shoes, and more.

Rigid Type

Water and Sewage Pipes:

Lightweight, durable, and cost-effective for fluid transmission.

Additives for Concrete and Asphalt:

Enhance mechanical strength.

Window Profiles:

An excellent alternative to wood and metal.

Credit Cards:

Durable, printable, and flexible bodies.

Interior Decorations:

PVC films for cabinets, wall panels, and false ceilings.

Why Is Choosing PVC a Smart Move for Manufacturers?

As a compound producer or supplier, choosing PVC allows us to add significant value to our products. Its easy processability, compatibility with a wide range of additives, and versatility of applications have made PVC the first choice for many major companies in the compounding industry.

Conclusion

In this article, we aimed to provide a comprehensive overview of PVC and its wide range of applications. If you’re considering developing new products or improving the quality of your existing compounds, PVC is an unmatched and reliable option. It is not only cost-effective but also holds a prominent position in the global market due to its outstanding physical and chemical properties.

So, if you’re looking for diversity, quality, and flexibility in production, PVC is exactly what you need.

Feel free to share your experiences using PVC in the production of various products with us.